Project

Emergency Repair Work

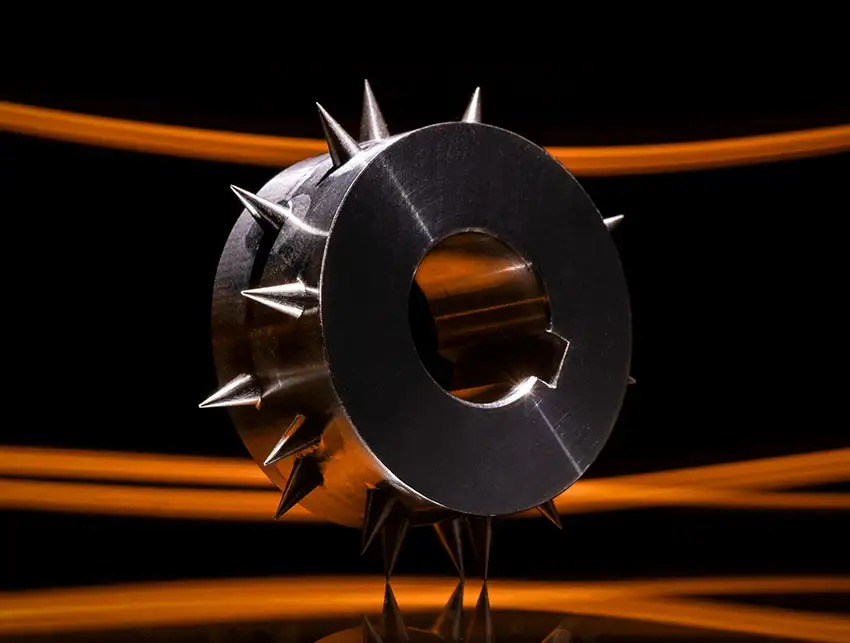

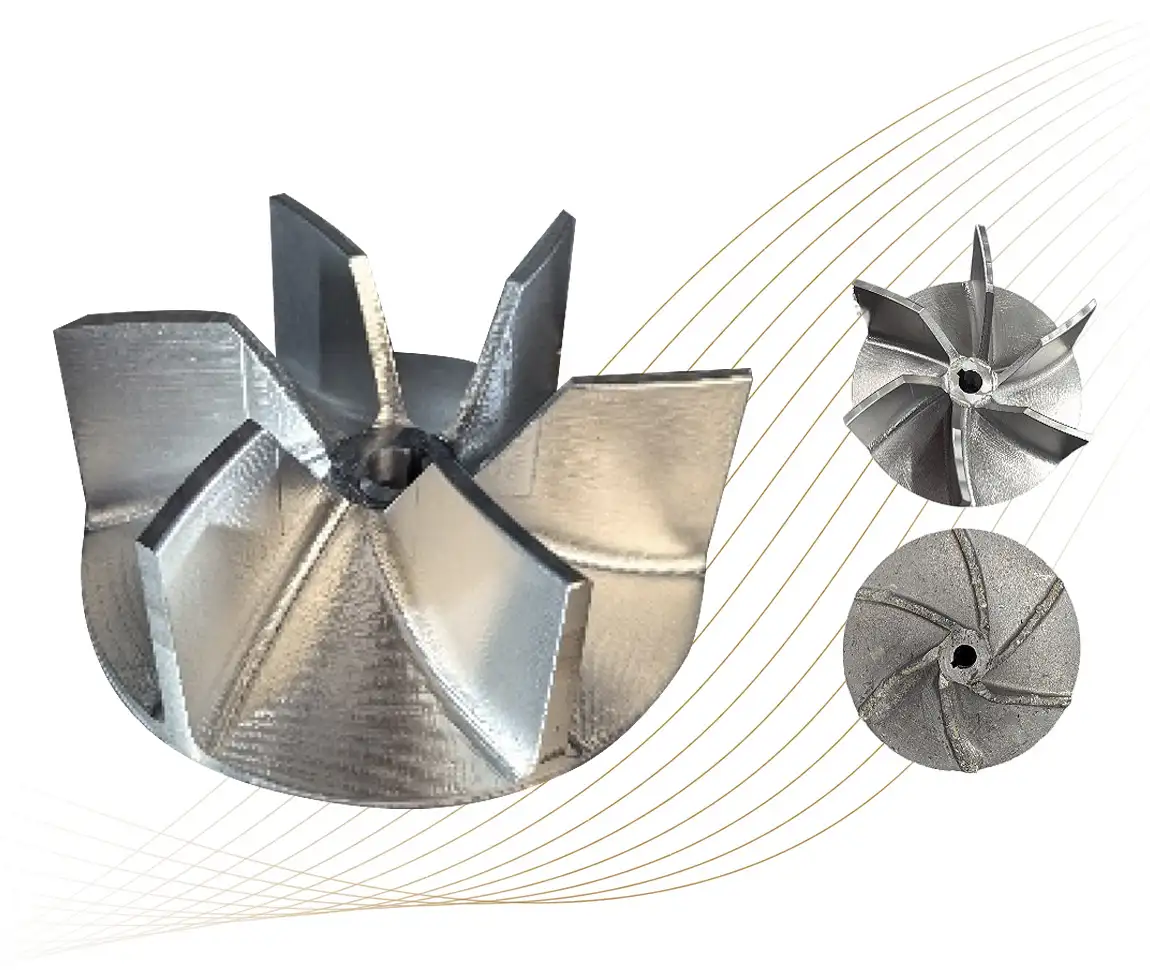

Avonside Engineering specialises in emergency breakdown repair work. A recent project involved producing a replacement fan for a floor sanding machine. The customer, unable to source the part anywhere in the UK after a critical breakdown on site, turned to Avonside for a solution. A 3D model of the original component was created and approved by the client. Following approval, the part entered production, initially machined on a Doosan Lynx Lathe to form the outside diameter, bore, and internal keyway. It was then programmed using OneCNC CAD/CAM software and transferred to the Hurco VM20 for precise machining of the fan blades.

Once completed, the component was successfully fitted into the floor sanding machine, ready for collection and return to site.