Article

Ryder Cup Driver Technology – Engineering the Trampoline Effect in Golf Drivers

Understanding the science, benefits, and regulations behind modern driver technology

The trampoline effect in golf drivers represents one of the most significant technological advances in golf equipment over the past two decades. This phenomenon, which occurs when the clubface deforms and rebounds upon impact with the ball, has revolutionised distance capabilities for golfers at all skill levels while simultaneously creating new regulatory challenges for golf's governing bodies.

The Science Behind the Trampoline Effect

Basic Physics

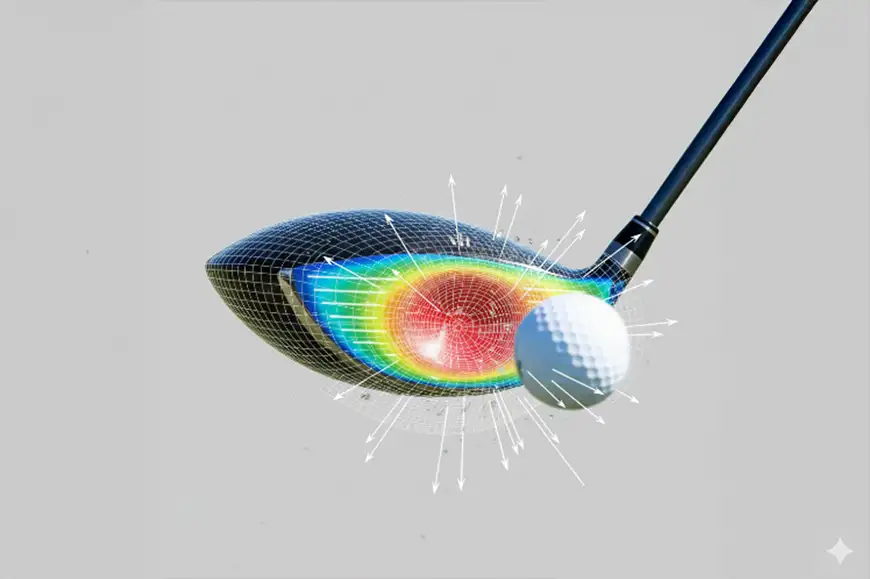

The trampoline effect is fundamentally based on the principle of elastic energy storage and release. When a golf ball strikes the driver face at high velocity, the thin titanium face deforms inward, temporarily storing kinetic energy as elastic potential energy. As the face springs back to its original position, this stored energy is released, adding to the ball's velocity beyond what would be achieved with a perfectly rigid clubface.

Key Factors

1. Face Thickness

Modern driver faces typically measure between 2.5-3.5mm thick, optimised for maximum flex without structural failure.

2. Material Properties

Titanium alloys, particularly Ti-6Al-4V (6% aluminium, 4% vanadium), provide the ideal combination of strength, elasticity, and weight for trampoline effect optimisation.

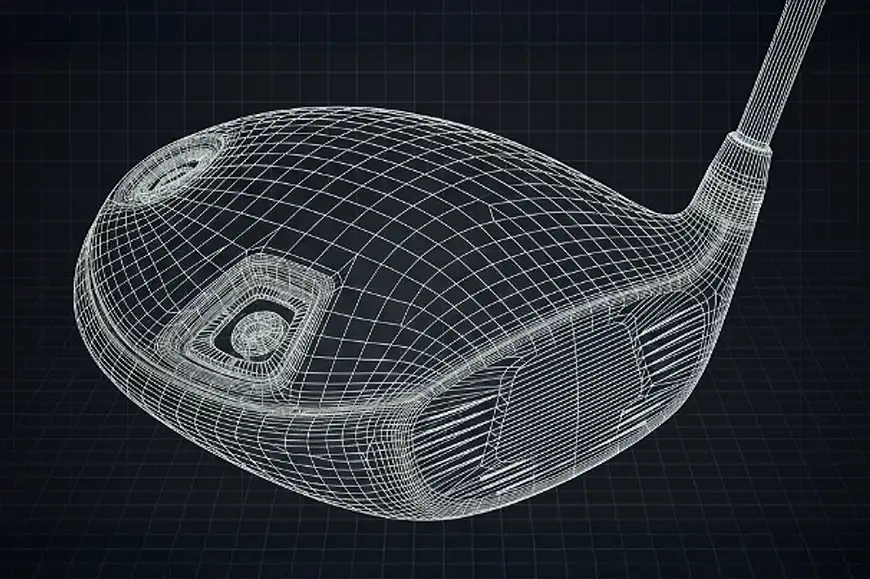

3. Face Architecture

Variable face thickness designs create zones of optimal flex across the striking surface.

4. Ryder Cup Performance Data

Analysis of driver performance during the 2023 Ryder Cup at Marco Simone Golf Club demonstrated the practical engineering implications of trampoline effect optimisation. European team members averaged 181.2 mph ball speeds with conforming drivers, while achieving carry distances exceeding 320 yards on Roma's demanding layout. The consistent performance under competitive pressure validated the engineering reliability of modern face designs operating at maximum regulatory limits.

Engineering and Design

1. Manufacturing Innovations

Modern driver faces are precision-engineered using advanced manufacturing techniques:

- Chemical milling to create variable thickness patterns

- Forging processes for consistent material properties

- Heat treatment to optimise elasticity and durability

- CNC machining for precise thickness control

2. Design Philosophy

Engineers must balance multiple competing factors:

- Maximum allowable spring effect within regulations

- Durability under repeated high-speed impacts

- Weight distribution for optimal centre of gravity

- Manufacturing cost considerations

Benefits for Golfers

1. Distance Gains

The primary advantage of the trampoline effect is increased ball speed and distance. Research indicates:

- Ball speed increases of 5-10 mph compared to rigid faces

- Potential distance gains of 15-25 yards for average golfers

- Enhanced performance particularly beneficial for slower swing speeds

2. Forgiveness

The flexible face design provides:

- Maintained ball speed on off-centre hits

- Larger "sweet spot" for consistent distance

- Reduced distance penalty for mishits

3. Accessibility

The technology has made golf more accessible by:

- Helping recreational golfers achieve satisfying distances

- Reducing physical demands for distance

- Maintaining enjoyment for aging golfers

Drawbacks and Limitations - Performance Concerns

1. Distance Control

Enhanced ball speed can make precise yardage control more challenging, particularly for skilled players who rely on exact distances for course management.

2. Consistency Variations

The trampoline effect can vary based on:

- Ambient temperature

- Swing speed

- Impact location

- Club aging and wear

3. Feel and Feedback

Many golfers report:

- Different impact sensation compared to traditional clubs

- Less solid feedback at impact

- Reduced ability to "feel" the quality of contact

4. Durability Issues

Thin, flexible faces may experience:

- Stress fractures over time

- Performance degradation with use

- Higher replacement costs

Golf Regulations and Rules

Regulatory Framework

The United States Golf Association (USGA) and The Royal and Ancient Golf Club of St Andrews (R&A) jointly govern equipment regulations through comprehensive testing protocols.

Key Measurements

1. Coefficient of Restitution (COR)

- Maximum allowed: 0.830

- Measures the efficiency of energy transfer

- Tested using a standardised pendulum apparatus

2. Characteristic Time (CT)

- Limit: 239 microseconds (tolerance to 257 microseconds)

- Measures ball-face contact duration

- Correlates directly with spring-like effect

3. Implementation Timeline

- 1998: Initial COR limits proposed

- 2003: COR limit of 0.830 implemented

- 2004: CT test introduced as secondary measure

- 2008: Stricter enforcement and testing protocols

4. Non-Conforming Equipment

Clubs exceeding regulatory limits are classified as "non-conforming" and are:

- Prohibited in official competition

- Available for recreational use

- Often marketed for maximum distance performance

Impact on Equipment Development

Technological Evolution

Regulation limits have pushed manufacturers toward alternative innovations:

1. Aerodynamic Improvements

- Streamlined head shapes

- Reduced drag coefficients

- Optimised airflow patterns

Ryder Cup Manufacturing Standards: The 2025 Ryder Cup requires all competing drivers to undergo enhanced USGA testing protocols, with samples from each manufacturer tested at Marco Simone's elevation (approximately 200m above sea level). Manufacturing precision became critical as atmospheric pressure variations of 2-3% could shift CT measurements by 1-2 microseconds, requiring tighter manufacturing tolerances of ±0.03mm face thickness control versus the standard ±0.05mm to ensure regulatory compliance across varying conditions.

2. Weight Distribution

- Moveable weight systems

- Low and back CG positioning

- MOI optimisation

3. Adjustability Features

- Loft and lie adjustment

- Face angle modification

- Weight positioning options

4. Market Implications

The regulatory ceiling has created:

- Standardised performance baselines

- Focus on fitting and customisation

- Emphasis on non-performance features (aesthetics, adjustability)

Conclusion

The trampoline effect represents a pivotal development in golf technology, successfully increasing distance capabilities while maintaining equipment integrity through careful regulation. While the technology offers significant benefits for recreational golfers, the implementation of strict limits ensures that skill remains the primary determinant of performance at competitive levels.

Understanding the trampoline effect helps golfers make informed equipment decisions and appreciate the engineering complexity behind modern golf drivers. As technology continues to advance within regulatory constraints, future innovations will likely focus on optimisation within existing limits rather than pushing beyond current performance thresholds.

Ryder Cup Durability Insights: The intensive practice schedules leading up to Ryder Cup competitions provide unique durability validation. Players like Scottie Scheffler and Tommy Fleetwood typically hit 200-300 drives daily during preparation weeks, representing accelerated fatigue testing equivalent to 3-6 months of recreational use. Equipment managers reported that modern Ti-6Al-4V faces showed no measurable performance degradation after this intensive use, validating S-N curve-based fatigue analysis and confirming engineering safety margins.

Interested in discussing any points raised in this article?

Contact us today and speak to one of our team who will be happy to assist you with your enquiry.

Back to Knowledge Base