Article

Unmasking the Magic of 4th Axis Milling: A Spooktacular Journey into Precision Machining

When it comes to precision engineering, some capabilities can seem almost supernatural. 4th axis milling is one such technology that conjures up remarkable results, transforming complex machining challenges into achievable realities.

At Avonside Engineering, we're thrilled to carve out the details of this hauntingly impressive process, and what better way to demonstrate its spine-tingling capabilities than by machining a Halloween pumpkin from 6082 T6 aluminium billet?

What Bewitching Powers Does 4th Axis Milling Possess?

Traditional 3-axis CNC milling machines move a cutting tool along three linear axes (X, Y, and Z). However, 4th axis milling adds a frightfully clever rotational axis, typically the A-axis, which rotates the workpiece during the machining process. This additional movement unlocks a whole new dimension of manufacturing possibilities that would otherwise remain trapped in the shadows of impossibility. Think of it as the difference between carving a pumpkin whilst it sits stationary on your kitchen table versus being able to spin it effortlessly as you work. The latter approach reveals every angle, every contour, and every intricate detail without the nightmarish task of constantly repositioning your workpiece.

The Hair-Raising Benefits That Will Leave You Spellbound

Banishing Multiple Setups to the Graveyard

One of the most ghoulish aspects of traditional machining is the need for multiple setups. Each time a component must be repositioned or transferred to another machine, precious time vanishes into thin air, and the spectre of dimensional errors haunts the process. With 4th axis milling, complex geometries can be machined in a single setup, eliminating the phantom risks of misalignment and dramatically reducing production time. Your components emerge from the machine with consistent accuracy that's nothing short of magical.

Conjuring Complex Geometries with Ease

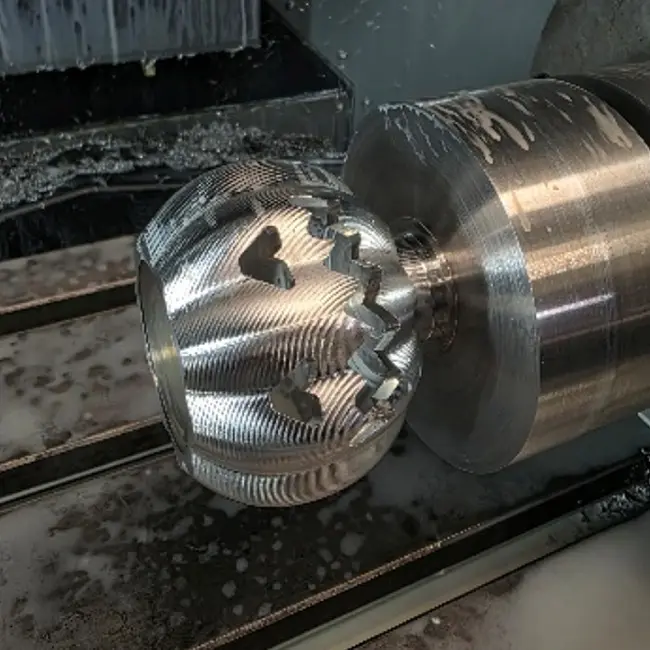

Certain features would be virtually impossible to machine using conventional 3-axis methods. Helical grooves, intricate radial patterns, and wraparound designs that would typically haunt engineers with complexity become achievable with 4th axis capabilities. The continuous rotation allows the cutting tool to bewitch the workpiece from every conceivable angle, creating features that would otherwise require elaborate fixturing or multiple operations that could frighten away even the most experienced machinists.

Summoning Superior Surface Finishes

The phantom menace of poor surface finish often lurks where tool access is limited. 4th axis milling exorcises this problem by maintaining optimal cutting angles throughout the machining process. The rotational capability ensures consistent chip evacuation and reduces the cursed vibrations that can plague surface quality. The result? Components emerge with bewitchingly smooth finishes that require minimal post-processing.

Slashing Production Time Without Fear

Time is money in manufacturing, and 4th axis milling performs its magic by significantly reducing cycle times. By eliminating the need to manually reposition workpieces or transfer them between machines, production flows with supernatural efficiency. What might have taken hours using traditional methods can be accomplished in a fraction of the time, allowing you to conjure more components and keep the spectre of deadline pressure at bay.

Achieving Bone-Chilling Precision

Precision is the lifeblood of engineering excellence. Every time a workpiece is repositioned, the potential for error creeps in like an unwelcome ghost. With 4th axis milling, components remain secure in a single setup throughout the entire machining process, maintaining datum references that ensure dimensional accuracy so precise, it's almost supernatural. This is particularly spine-tingling for components requiring features on multiple faces with tight tolerances.

The Pumpkin Project: Where Engineering Meets Halloween Spirit

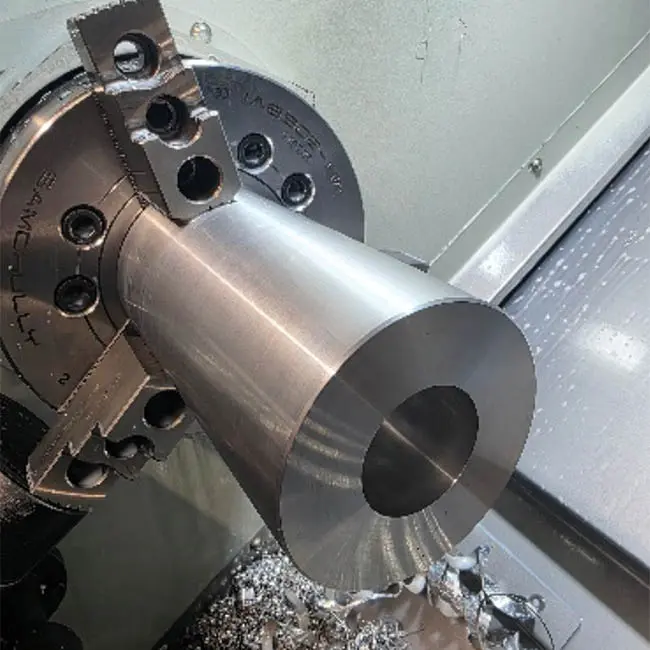

To showcase the enchanting capabilities of 4th axis milling, we've undertaken a delightfully frightening project: machining a detailed pumpkin from 6082 T6 aluminium billet. This material, known for its excellent machinability and bewitching combination of strength and corrosion resistance, provides the perfect canvas for our Halloween creation.

The project demonstrates how 4th axis technology can conjure intricate details, from the curved surfaces of the pumpkin's body to the characteristic ridges that haunt its exterior. Without the rotational axis, creating such organic, flowing features would be a nightmare of multiple setups and compromised geometry. With 4th axis milling, the pumpkin emerges from the billet as if summoned by dark magic itself, each detail captured with frightening accuracy.

Why This Matters for Your Manufacturing Needs

Whether you're producing one-off prototypes or casting spells for high-volume production runs, 4th axis milling capabilities can transform your project from merely good to hauntingly exceptional. At Avonside Engineering, our advanced CNC machinery is equipped to tackle the most challenging specifications, ensuring components are manufactured with the precision and quality that your application demands.

The benefits transcend the novelty of machining decorative pumpkins. Industries requiring complex cylindrical components, aerospace parts with intricate radial features, medical devices with precise geometries, or automotive components with multiple machined faces all benefit from the supernatural precision that 4th axis milling provides.

Bringing Your Vision to Life Without the Fright

If your project demands precision engineering with complex geometries, Avonside Engineering is equipped to deliver results that will leave you spellbound rather than spooked. Our comprehensive range of advanced CNC milling machinery, combined with expert capabilities, ensures your requirements are met with efficiency and quality that's anything but frightening.

From your initial consultation through to final delivery, we maintain ongoing communication throughout the process, ensuring your project progresses smoothly without any nasty surprises lurking in the shadows. Whether you're working to detailed specifications or facing unique engineering challenges that seem to haunt your production plans, our team is ready to help conjure your vision into reality.

CNC Milling Pumpkin - Frighteningly Good 4th Axis Work

Ready to unlock the bewitching potential of 4th axis milling for your next project?

Contact Avonside Engineering today for a free initial consultation. Let's carve out success together.

Back to Knowledge Base